A hybrid filter system has been developed as an air pollution control device that closely integrates electrostatic precipitation (ESP) and fabric filter technologies into a durable, cost-effective device that produces superior filtration results. Its design uses a synergy between these two technologies whereby the filter bags are able to operate at high air-to-cloth (A/C) ratios than conventional pulse jet fabric…

Electrostatic Precipitator

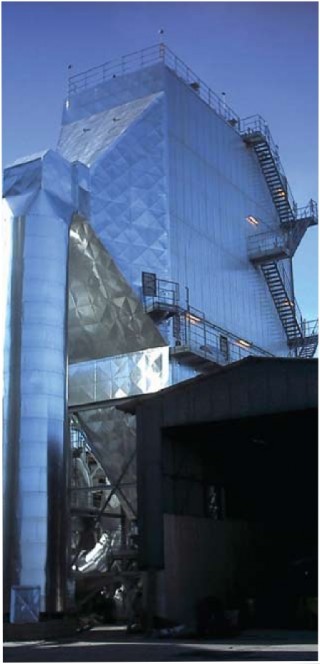

Electrostatic precipitators have been used in many industries; several examples are cement, steel, aluminum, copper, ceramic, tile, petrochemical and power plant. An electrostatic precipitator is a large, industrial emission-control unit. They can handle large gas volumes with a wide range of inlet temperatures, pressures, dust volumes, and acid gas conditions.

Electrostatic precipitators have been used in many industries; several examples are cement, steel, aluminum, copper, ceramic, tile, petrochemical and power plant. An electrostatic precipitator is a large, industrial emission-control unit. They can handle large gas volumes with a wide range of inlet temperatures, pressures, dust volumes, and acid gas conditions. They can collect a wide range of particle sizes, and they can collect particles in dry and wet states. For many industries, the collection efficiency can go as high as 99.99%. Precipitators function by electrostatically charging the dust particles in the gas stream. Particles suspended in a gas enter the precipitator and pass through ionized zones around the high voltage discharge electrodes. The electrodes, through a corona effect emit negatively charged ions into the gas. The negatively charged gas field around each electrode charges the particles causing them to migrate to the electrodes of opposite polarity, i.e. the collecting electrodes. When enough dust has accumulated, the collectors are shaken to dislodge the dust, causing it to fall with the force of gravity to hoppers below. The dust is then removed by a conveyor system for disposal or recycling.

In abbreviation six activities typically take place:

- Ionization - Charging of particles

- Migration - Transporting the charged particles to the collecting surfaces

- Collection - Precipitation of the charged particles onto the collecting surfaces

- Charge Dissipation - Neutralizing the charged particles on the collecting surfaces

- Particle Dislodging - Removing the particles from the collecting surface to the hopper

- Particle Removal - Conveying the particles from the hopper to a disposal point

Probably the best way to gain insight into the process of electrostatic precipitation is to study the relationship known as the Deutsch-Anderson equation. This equation is used to determine the collection efficiency of the precipitator under ideal conditions.

The simplest form of the equation is given below.

Efficiency = 1-e (Aw /Q)

Where A is the collecting electrode surface area (m2), w is the precipitation rate (cm/s) and Q is the gas volume (m3/s).

Migration velocity is the speed at which a particle, once charged, migrates toward the grounded collection electrode. Variables affecting particle velocity are particle size, the strength of the electric field, and the viscosity of the gas. How readily the charged particles move to the collection electrode is denoted by the symbol, w, called the particle-migration velocity, or drift velocity. The migration-velocity parameter represents the collectability of the particle within the confines of a specific ESP.

Although the physical operation of a precipitator is simple and essentially the same for each industry, the sizing of a precipitator is more complex combining both art and science. Factors that influence precipitator sizing are:

- Gas volume

- Precipitator inlet loading

- Precipitator outlet loading required

- Outlet opacity required

- Particulate resistivity

- Particle size

The major precipitator components that accomplish these activities are as follows:

- Discharge Electrodes

- Collecting plates

- Precipitator Control units

- Rapping Systems

Related Posts

- Hybrid Filter

- Cyclone

The primary function of a cyclone is to separate dust from a gas stream. After separation, the dust discharges out the bottom of the cyclone and air discharges through the top exhaust. Cyclones (or centrifugal collectors) create a ‘cyclonic’ or centrifugal force, similar to water going down a drain, to separate dust from the polluted air stream.

- Wet scrubber

Wet scrubbers are industrial devices for removing dust from gases by spraying liquids. These de-dusting device compared to the others, have some advantage.